Iglasi yeceramic emhlophe

Iglasi emhlophe-iCeramic yePaneli yePlate yokuPheka, iZixhobo zeKhitshi zale mihla

I-Kanger Ceramic Glass R&D ngezinto ezikhethekileyo zeglasi, olona phawu lubalulekileyo lwezinto eziphathekayo luyakwazi ukuthwala ukunyuka ngokukhawuleza kwamaqondo obushushu ukuya kuthi ga kwi-650 ° C. icutshungulwe ngokweesayizi ezahlukeneyo, iglasi iphuhliswe ngokukodwa kwaye yenzelwe isitovu sasekhitshini.I-permeability yamagnetic egqibeleleyo kunye ne-thermal conductivity, ukumelana nobushushu obuphezulu, iglosi elungileyo, iziva ithambile kwaye igudileyo, i-discoloration yokusetyenziswa kwexesha elide, i-deformation, kulula ukuyicoca, I-stylish and elegant.Ngoko iglasi yeKanger ibe yeyona nto iphambili kwimarike, ithandwa ngabathengi.Iphaneli yeglasi yeceramic esiyiqhubayo ihambelana kakhulu nokusingqongileyo, eyona nto iphambili ye-quartz, le nto ayipheli kwindalo.

-

• I-Coefficient ye-thermalExpansionis iphantse ifikelele kwi-zero

• Uzinzo lobushushu kunye nokuqina

• Uzinzo lomatshini luphezulu -

• Ugqithiso lwenkqubo ye-infrared

• I-thermal conductivity ephantsi

• Ukumelana nokothuka kwe-thermal

Iimveliso Iinkcukacha

I-Kanger emhlophe yeglasi-i-ceramic izisa ifashoni kunye nesitayile sobutofotofo kwiikhitshi zangoku.Imibala eyahlukeneyo yokuhlobisa ingasetyenziselwa ukwenza ngokwezifiso uyilo.Ukuqinisekisa ukuba i-design jikelele iyahambelana, i-color scheme yenza ukuba uyilo lube nobuchule obungenamkhawulo.I-Kanger Idibanisa ubulumko kunye nokuphefumlelwa kwi-teknoloji ye-microcrystalline yanamhlanje izinikele ekudaleni ingcamango yobomi bokukhusela indalo, ukubonelela ngeephakheji zomntu.Olona phawu lubalulekileyo lweglasi yeceramic inokuthwala ukunyuka okukhawulezileyo kwamaqondo obushushu ukuya kuthi ga kwi-750 ℃.Inomgangatho ophantsi kakhulu wokwandiswa kwe-thermal, ukufikeleleka okugqibeleleyo kwemagneti kunye nokuhanjiswa kwe-thermal, ukumelana nobushushu obuphezulu, iglosi elungileyo, uzive uthambile kwaye ugudile.Kwakhona kulula ukucoca, non-deformationemva kokusetyenziswa kwexesha elide.

Isicelo

I-1) I-induction / infrared cooker plate: iglasi ye-ceramic inokuthwala ukunyuka ngokukhawuleza kwamaqondo obushushu ukuya kwi-650 ℃.Ine-coefficient ephantsi kakhulu yokwandiswa kwe-thermal.Inokungena ngokugqibeleleyo kumagnethi kunye ne-thermal conductivity, ukumelana nobushushu obuphezulu, isicwebezelisi esihle, ivakale ithambile kwaye igudileyo ukuthungwa, ukusebenzisa ixesha elide i-discoloration, ukungaguquki, kulula ukuyicoca.

2)Isitovu sokupheka segesi/Iphaneli yesitovu esixutyiweyo: Inomlinganiso ophantsi kakhulu wokwandiswa kobushushu kunye nokumelana nokothuka kwe-thermal, kwaye inokucutshungulwa ngokweesayizi ezahlukeneyo, iglasi ephuhliswe ngokukodwa kwaye iyilelwe isitovu sasekhitshini.

3) Izixhobo zokufudumeza: iipaneli zokufudumeza, izifudumezi ze-infrared, iipaneli ze-infrared bath heater, iipaneli zokufudumala, kunye neemveliso ezintsha ezifana nemizobo yokufudumala.

I-4) Ukunakekelwa kwezonyango kunye nempilo: Iipaneli zesixhobo se-infrared physiotherapy, iipaneli ze-pedicure, iipaneli zokufudumeza i-infrared, iipaneli zezempilo zebhodwe le-infrared, ii-coasters zezempilo kunye nezinye iimveliso.

5)Izixhobo zasekhaya: iiphaneli zee-oveni zemicrowave, iigrill, ii-oveni, ii-rice cookers, oomatshini bekofu nokunye.

ITekhnoloji yoLungiso

Isishwankathelo semilinganiselo: iipaneli ezisikiweyo ukuya kubukhulu

| Ukutyeba | Ubude obuqhelekileyo | Ububanzi obuqhelekileyo |

| 4 mm | 50-1000 mm | 50-600 mm |

| 5 mm | 50-1000 mm | 50-600 mm |

| 6 mm | 50-1000 mm | 50-600 mm |

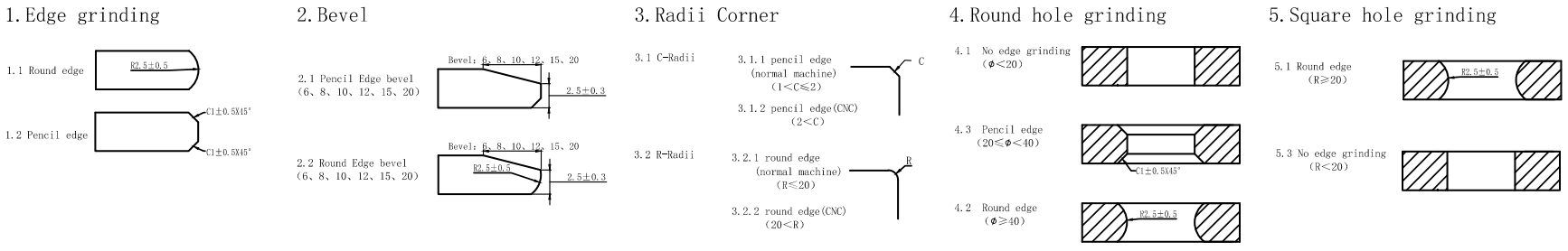

IiProfayili zokugaya

Iindlela zokuSebenza

1. Ukucheba

2. Ukujija, ukurhawuzelela, ukugudisa

3. Ukusika amanzi, ukugaya

4. Ukuprintwa, ukuhombisa, i-decals

5. Ukwaleka

Inkqubo yeMveliso

UkuHamba kweNkqubo 1

Irow material—Molding—Annealing Furnace—Crystallization—Ukuhlolwa koBulunga

Inkqubo Flow2

Izinto eziluthotho—I-Molding—Annealing Furnace—Crystallization—Ipolishi—Ukuhlolwa koBulunga

Inkqubo Flow3

Cutting—Flanging, chamfering—Shicilela—Uhlolo lokugqibela lweMveliso—Iphakheji—Ukuhanjiswa